Greeting

There are records that indicate that the winch appeared as a convenient machine for people in ancient Greece in 480 BC. Today, people make cities higher and higher and deeply expanding the scope of activities in search of reserves in the ocean. MAXPULL WINCH supports on-site work from high altitude to deep sea exploration with our customers.

The winch

We are a manufacturer specializing in winches which is rare in today’s world. As a specialist of “lifting” and “pulling”, MAXPULL WINCH will contribute to society while globally expanding bases of activity utilizing the know-how and technology we have cultivated based on a slogan [Gravity is our only rival!].

Management philosophy

Guideline

Setting high goals and comparing yourself to your current self / counting backwards to draw a clear route to achievement

Achievement of high goal is a result of accumulated sure steps.

Conducting yourself based on accuracy without a single cloud

Trying to be perfect and doing your best

Moving by yourself and changing yourself

Speed is power, always think positive

Guideline of organization

Each and every one of us practices management based on unshakeable facts.

We value our customers, employees, shareholders, and society.

We pursue profit fairly as a result of creating social value.

In order to maintain a revitalized organization, we will disclose and share information, and engage in frank and constructive communication.

Each of us creates true teamwork as a professional.

Company profile

|

|

|

| Company name | MAXPULL MACHINERY & ENGINEERING CO., LTD. |

|---|---|

| Head office | 1296-22, Nakaya, Nishifukai, Nagareyama-shi, Chiba Nagareyama Industrial Park TEL 04-7186-6797 FAX 04-7186-6798 |

| West Japan Sales Office | 3-4-25, Sakuragawa, Naniwa-ku, Osaka-shi, Osaka TEL 06-6567-2388 FAX 06-6567-3088 |

| Affiliate company | MAXPULL USA CORPORATION 788 110th Avenue NE, Suite #N-1404 Bellevue, Washington USA 98004 TEL +1(425)443-2111 http://www.maxpullusa.com/ |

| Executive officer | President and CEO Koichi Ono |

| Capital fund | 13 million yen |

| Start of business | January 31, 1976 |

| Business items | Manufacturing / sales of MAXPULL WINCH Design / manufacturing / sales of various manual / electric winches Design / manufacturing / sales of industrial machines |

| Equipment | Load test tower, etc. |

| Banking relationship |

The Shoko Chukin Bank, Ltd. Matsudo Branch |

History and development

| September 2021 | Participated in SDGs as “Goals to be achieved by 2030 for human beings to continue living on this earth” |

|---|---|

| May 2017 | Succeeded in the improvement of MAXPULL hand winch to RoHS Directive compliant product for environmental protection. Sales started. |

| March 2016 | Overseas affiliated company MAXPULL USA CORPORATION was established in Washington State, United States. Concluded agency contracts with 10 companies in 8 countries including Asia and Europe. |

| October 2015 | Merged Tokyo Head Office and Saitama Yashio Factory / Yashio Warehouse and newly constructed and transferred Head Office / Factory to Nagareyama Industrial Park, Chiba. Business started. |

| October 2014 | Succeeded in the development of electric reciprocating traction winch in world’s smallest size EMX-150 type. At the same time, also succeeded in the development of wireless control panel dedicated to the model. Combined sale started. |

| March 2014 | Acquired international standards for quality management ISO9001:2008 as an entire company. |

| September 2013 | Developed world’s first double drum hand reciprocating traction winch ME series and started manufacturing and sales. |

| September 2013 | JETRO (Japan External Trade Organization) adopted MAXPULL WINCH as promising export projects discovering support business. At the same time, overseas sales department inaugurated. Exhibit at overseas exhibition focusing on Asia started. |

| March 2012 | Succeeded in the CE standard certification / acquisition for the first time as a domestic independent winch manufacturer by TRaC Global Ltd in UK. |

| September 2010 | CEO Goki Ohgushi retired and became chairman. Director Koichi Ono became CEO. |

| March 2008 | Reciprocating traction type hot-dip galvanized hand winch for large wind turbine generation turbine for coastal / marine installation was developed and manufactured. Delivery started. |

| June 2007 | Reciprocating traction type hand winch for large wind turbine generation turbine was developed and manufactured. Delivery started. |

| November 2006 | Koichi Ono became a director. |

| October 2005 | For National Institute of Polar Research 47th Antarctic Wintering Expedition Winch system for Antarctic sediments sound probe endless winch EME-200-DSU type was delivered. |

| September 2002 | Chairman and Representative Director Iwao Takahashi retired and became an advisor. |

| February 2002 | For TOKYO GAS CO., LTD., special electric winch for internal cleaning of pipeline, MWS-2500-TR-IV was developed, manufactured, and delivered. |

| October 1999 | For Saitama Super Arena, electric winch for pulling artificial grass, MWS-3000-TR-IV type was developed, manufactured, and delivered. |

| January 1999 | Representative Director Iwao Takahashi retired and became Chairman and Representative Director. Senior Managing Director Goki Ohgushi became CEO. |

| December 1996 | Captain Fujii of Antarctic Expedition reported that deep ice drilling of Antarctic dome project reached 2,500m in 1 year and 3 months after starting drilling and the project was successful |

| November 1996 | Chairman and Representative Director Tetsuo Goto retired from Representative Director. |

| October 1996 | Manufacturing and samples of 12 models of parallel winches with built-in motor BMW-201 type to BMW-503 type started. |

| June 1996 | Development, manufacturing, and sales of reciprocating traction endless winches EME-400 type, EME-700 type, EME-1300 types started. |

| November 1995 | Electric winch MAW-1100 type was mounted on Icebreaker Shirase of 37th Antarctic Expedition and went to the Antarctic Pole. |

| November 1993 | Electric / manual combined winch GME-120H type for lifting maintenance lift for bay bridge tower was developed and manufactured, delivered to Japan Highway Public Corporation. |

| October 1993 | Cold-resistant special electric winch MAW-1100 type for Antarctic dome project and ice sheet drilling equipment was developed and manufactured, and delivered to National Institute of Polar Research. Hoisting ability = 1,000kg Winding speed = 0.1m to 49m/min Cable = 7-core armored wire Φ7.72mm x 3,500m |

| April 1993 | Forced drawing type electric endless winch EME-1300 type for golf driving range ball net lifting device was developed and manufactured, applied for a patent and started sales. |

| November 1992 | Participated in Deep Ice Coring Project at Dome Fuji, Antarctica (popular name, dome project) “clarifying changes in the global environment over 350,000 years and their reasons” of National Institute of Polar Research |

| June 1992 | Rope winch for removable mooring observation, SEA-M-400 type was developed and manufactured, and delivered to Ocean Research Institute The University of Tokyo (Tansei Maru). |

| June 1991 | Saitama Factory was opened as electric winch assembly and parts manufacturing factory at 3-13-1, Yashio-shi, Saitama-ken, two fully automatic welding devices equipped with shuttle table were introduced to start manufacturing. |

| November 1989 | Osaka Sales Office was opened at 3-4, Sakuragawa, Naniwa-ku, Osaka-shi. |

| October 1989 | The device was tested in the North Pole and succeeded in 500m ice core drilling. |

| March 1989 | Antarctic ice layer (for shallow layer) drilling device was developed and manufactured, and delivered to National Institute of Polar Research. |

| May 1988 | Wind speed interlocking system was introduced to golf driving range ball net lifting device, succeeded in automation of lifting system, sales started. |

| January 1988 | CEO Tetsuo Goto retired and became Chairman and Representative Director. Senior Managing Director Iwao Takahashi became CEO. |

| March 1985 | Succeeded in development of small winch for marine observation equipment, OCEANOGRAPHIC.REEL:MWS-35 type ensuring rust proof, weight saving, compactness, and high performance by adopting kevlar rope. It makes winding / unwinding work for water sampler, mud sampler STD (built-in type), etc. on small boat safe to contribute to significant reduction in work time. Delivered to Kumamoto University, Ocean Research Institute The University of Tokyo, KANSO TECHNOS CO., LTD., and Hokkaido University, etc. |

| November 1983 | Development and sales of winch for lifting CQ radio tower GMT-1500 type started. |

| October 1983 | Manufacturing and sales of electric winches for lifting ball net for golf driving range GME-800-GO and GME-1400-GO types, development and sales of centralized control system for the winches started. |

| February 1983 | Six models (100kg to 3,000kg) of manual winch MR series (ratchet handle mechanism type) and five models (100kg to 2,000kg) of hand winch MC series (capstan drum type) were manufactured and sales started. |

| August 1980 | Manufacturing of manual winches GM-50 type (5,000kg) and GM-100 type (10,000kg), and manufacturing and sales of special electric winch up to capacity 30 tons started. |

| April 1980 | Succeeded in development of weight-saved and labor-saved winch dedicated to mountain rescue GMH-210 type and auxiliary equipment for the first time as a domestic product and the sales started. Delivered to National Center for Mountaineering Education of The Ministry of Education, Tokyo Fire Department, Toyama Prefectural Police Headquarters, and Mountaineering Federation of Shiga Prefecture. |

| February 1980 | In addition to existing 5 models of manual winch GM series (100kg to 2,000kg), development and sales of manual winch for 3 tons GM-30 type, winch for stage equipment GM-1L type, and electric winch dedicated to lifting of ball net for golf driving range GME-1000 (1,000kg) started. |

| October 1978 | Winch manufacturing department was separated and got independent from Goto Machine Industry Co., Ltd. and manufacturing and sales were integrated. Batch business of winch manufacturing and sales department was implemented. Increased capital to 13 million yen. Tetsuo Goto became CEO. Goki Ohgushi and Iwao Takahashi became Senior Managing Director / President. |

| January 1976 |

Asked an industrial machinery manufacturer Goto Machine Industry Co., Ltd. to manufacture a hand winch. |

Major clients (Japanese alphabetical order)

- ICHINEN AXESS Corporation

- OBAYASHI CORPORATION

- Japan Coast Guard

- Kajima Corporation

- Katsuyama Kikai

- KAYABA SYSTEM MACHINERY Co., Ltd.

- Kawasaki Heavy Industries, Ltd.

- Kikusuzu Co., Ltd.

- Kiya Corp

- Kubota Corporation

- Ministry of Land, Infrastructure, Transport and Tourism

- National Institute of Polar Research

- Komatsu Ltd.

- KONDOTEC INC.

- SAWATARI Kikou .inc

- SHIMIZU CORPORATION

- G-NET CORPORATION

- Japan Marine United Corporation

- NIPPON STEEL CORPORATION

- TAISEI CORPORATION

- Taiyo Seiki Iron Works Co., Ltd.

- DAIDO Corporation

- TAKENAKA CORPORATION

- Tokyo Fire Department

- Atmosphere and Ocean Research Institute, The University of Tokyo

- Tomita Industry Co., Ltd.

- TRUSCO NAKAYAMA CORPORATION

- NICHIDEN Corporation

- Nippon Light Metal Company, Ltd.

- Hitachi, Ltd.

- Ministry of Defense

- MODEC, INC.

- MITSUI E&S Co., Ltd.

- Mitsubishi Heavy Industries, Ltd.

- YUASA TRADING CO., LTD.

- IHI Corporation

- JFE Steel Corporation

Acquisition of CE mark/ISO9001:2008

MAXPULL MACHINERY & ENGINEERING CO., LTD. acquired “ISO9001:2008” certification, which is an international standard of quality management system defined by International Organization for Standardization (ISO) on March 10, 2014 for the first time as a domestic independent winch manufacturer. Here reports that we also passed the surveillance audit on March 1, 2017.

■Background of acquisition

MAXPULL WINCH has about 70% market share in Japan and in recent years, we been highly evaluated by overseas customers because of our safety and design concept. While globalization progresses, establishment of business processes that comply with global standards is essential.

As the market expands and changes in this way, MAXPULL WINCH acquired “CE mark”, which is a proof of trust that meets the safety standards of EU member countries on July 17, 2012. While companies generally acquire it on their own, the company dared to have the product evaluated and documented by an external inspection agency (UK: TRaC Global Ltd).

For the subsequent acquisition of “ISO9001:2008” certification, a full-fledged preparation was started by organizing an ISO Promotion Committee, for example, recognizing that it is essential for strengthening of business foundation, facilitation of transactions, and promotion of sales in these global markets.

In Japan, there are many cases in which certification is obtained for each factory or office, however, the company worked to obtain certification company-wide, including indirect departments such as sales department and general affairs and accounting department in addition to manufacturing department and design department.

The reason why the entire company worked on ISO9001 was that the 2008 version of ISO9001 aimed to improve the overall performance of corporate management and we thought that it was necessary to build a system that improved customer satisfaction company-wide in order to acquire [true customer satisfaction].

The company have always strived to improve quality to provide good products and services. The introduction of ISO9001 has improved awareness in all departments and as the result, we can always deliver high quality products and services to our customers.

The acquisition of this “ISO9001:2008” certification has enhanced the international credibility of our products and has promoted the worldwide business development furthermore while the borderless world continues to progress in today’s world market.

We dared not proceed to easily acquire the new international standard, “ISO9001:2015”, but created and carried out “MAXPULLQS” for which

CEO Koichi Ono

Conversion to RoHS Directive compliant products

MAXPULL WINCH has about 70% market share in Japan and is rated as a top brand by users. We are deeply grateful to our customers who understand MAXPULL’s quality policy “providing products with better performance and higher safety” and supported us and purchased our products.

As a result of promotion of alternative technology that eliminates specific hazardous substances and procurement of materials and parts that do not contain more than a certain amount of specified hazardous substances based on MAXPULL’s environment policy “Leaving no negative impact on the future global environment by thoroughly eliminating harmful chemical substances contained in products”, MAXPULL WINCH succeeded in the manual winch’s “conversion to RoHS Directive compliant products” without asking customers to bear any new burdens.

We will move ahead with reforms in order to deliver higher quality and better service to everyone. We look forward to your continued patronage in the future.

CEO Koichi Ono

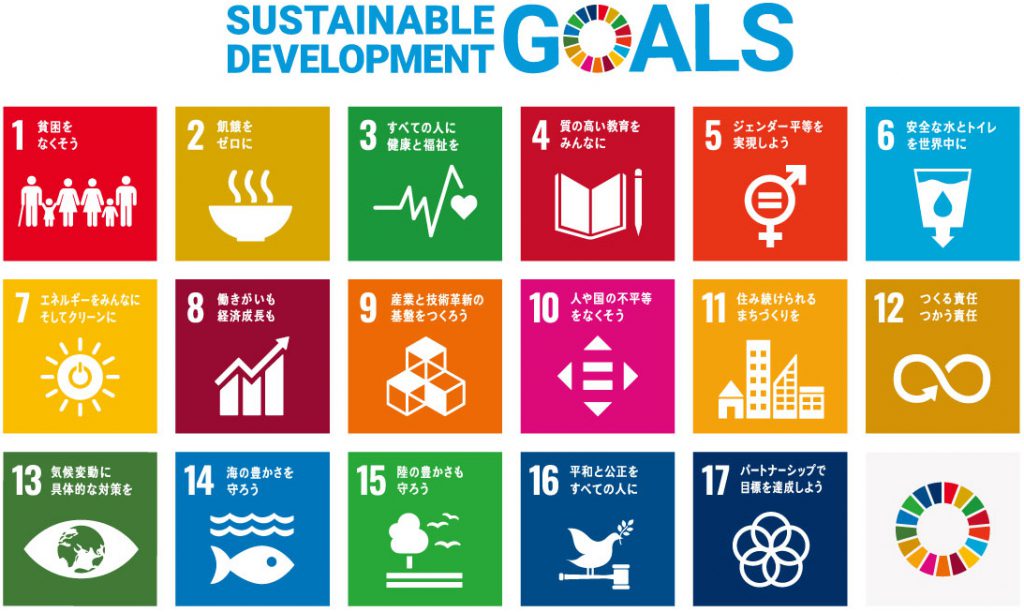

Initiatives for the achievement of SDGs

What are SDGs (Sustainable Development Goals)?

SDGs are international goals for a better and more sustainable world by 2030 described in “Transforming our world: the 2030 Agenda for Sustainable Development”, which were adopted unanimously by member states at the United Nations Summit in September 2015 as a successor to Millennium Development Goals (MDGs), which were formulated in 2001. SDGs are configured with 17 goals and 169 targets and make a commitment “leave no one behind” on the globe.

MAXPULL MACHINERY & ENGINEERING CO., LTD. participate in SDGs as “goals to be achieved by 2030 for human beings to continue living on this earth” and support “Goal 6” in “17 big goals”,

In the midst of the pandemic of the new coronavirus infection that threatens humanity, this is our current environment. The most important countermeasures against the new coronavirus infection is

Based on this fact, MAXPULL MACHINERY & ENGINEERING CO., LTD. funds activities for

Wate

As of 2021, WASH (Water, Sanitation, Hygiene) project is implemented in 26 countries in Asia, Africa, Latin America, etc. The expertise is utilized to find solutions that are suitable for the local situation so that poor people and people who tend to be left behind in each country can use clean water.

The world we live in, the world your children live in, and the world in which the next born children will live — in order to sustain this world, MAXPULL MACHINERY & ENGINEERING CO., LTD. will continue to strive.

CEO Koichi Ono