Features of capstan type manual winch MC series

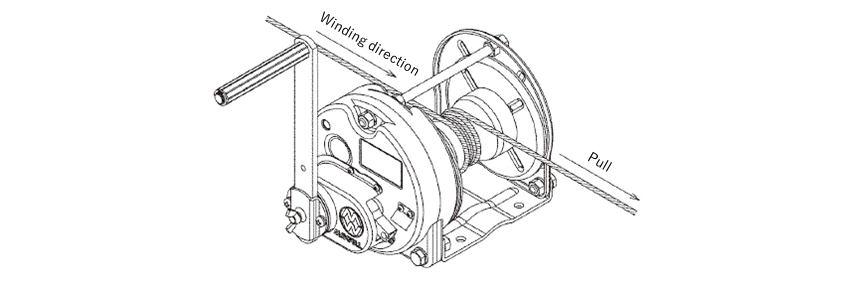

This is a horizontal pulling winch that can tow an object back and forth. It is necessary to wind the wire rope around the drum 5 to 7 times and using the handle to pull the wire rope by the same length as the wire rope wound up under tension.*Do not use MC series for lifting loads vertically.

Model: MC-1 / MC-3 / MC-5 / MC-10 / MC-20

![]()

![]()

Simple operation

As the machine efficiency is high, the hand load during operation is very light compared to that of competitors’ winches and you can carry out the work easily. This winch has a compact design with minimal weight and very convenient to carry or move. In addition, the main unit can be easily attached using predefined bolts. Another major feature is that each part is made by press processing, and the whole winch is assembled with bolts, so it can be easily disassembled. If a repair is necessary, anyone can easily repair and assemble the winch by following the instruction manual and purchasing the parts.

Exceptional durability

Ball bearings from leading manufacturers are used for all of our winch products. These ball bearings make the winding process light and exhibit outstanding strength against wear. For the reducer, our company’s custom designed heat treated gear uses an unique transposition method to allow the user to work with ease. The mechanical brake also has a mechanism that freely adjusts the gap so it is extremely durable. All surfaces are painted and treated which makes the winch resistant to rust with unrivaled durability in any working environment.

Reliable safety

This winch is extremely safe because of carefully selected material parts, advanced design and technology. Especially for the parts where load is applied in a concentrated manner, the strength is further increased by combining ribs or double plates made by precision press processing. The mechanical brake has a double safety mechanism, so even if there is an impact applied to the claw arm, the brake will remain in place. The wire rope is fixed to a specially designed drum using a double safety structure. The end of the wire rope can be easily fixed to the drum using a Hex key L-wrench included with the product. This MAXPULL original design ensures a highly reliable and safe product.

Cautions on handling

Do not use the capstan winch to lift loads vertically. This winch is only suitable for horizontal pulling trolleys, etc. Tension is required on the hand pulling side.

● With a MC type winch, it is necessary to wind the wire rope around the middle of the warping drum (capstan drum) 5 or 7 times and pull the same length of the wire rope that has been wound around the drum while operating the handle. It is necessary to apply tensile force (tension) to the wire rope side to be pulled and preventing the drum and wound wire rope from sliding. Please refer to the table shown below for the tensile force required on the wire rope.

| Model | MC-1 | MC-3 | MC-5 | MC-10 | MC-20 |

|---|---|---|---|---|---|

| Tensile force to be pulled | 20N or more (2kgf or more) |

40N or more (4kgf or more) |

69N or more (7kgf or more) |

128N or more (13kgf or more) |

245N or more (25kgf or more) |

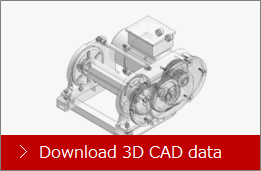

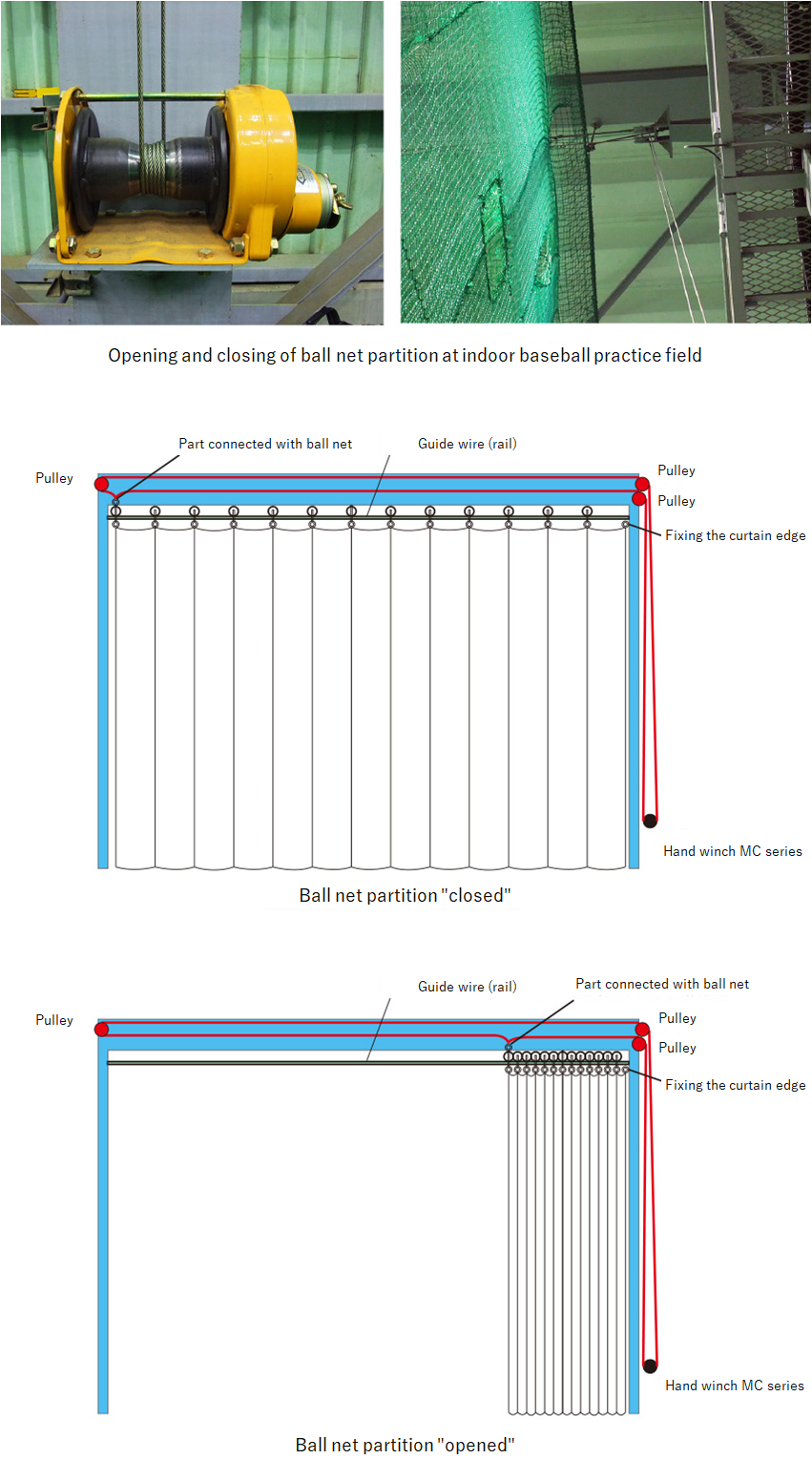

Examples of MC series usage site

Capstan type manual winch MC series product list

Model: MC-1 : 100kgf (220lbs)

| Model | MC-1 |

|---|---|

| Load Rating | 100kgf(220lbs) |

| Wire Rope Diameter | φ5mm (6×19) (3/16inch (7×19)) |

| Winding Wire Rope | 5 or 7 Wraps |

| Hauling Tension | 2kgf or more (4.4lbs or more) |

| Gear Ratio | 1 : 1 |

| Handle Force | 12.4kgf (27.3lbs) |

| Handle Length (Effective Maximum) | 250mm (9.84inch) |

| Weight (Main unit + Handle) | 8.9 kg (19.6lbs) |

Model: MC-3 : 300kgf (660lbs)

| Model | MC-3 |

|---|---|

| Load Rating | 300kgf (660lbs) |

| Wire Rope Diameter | φ6mm (6×37) (1/4inch (6×36)) |

| Winding Wire Rope | 5 or 7 Wraps |

| Hauling Tension | 4kgf or more (8.8lbs or more) |

| Gear Ratio | 6.25 : 1 |

| Handle Force | 6.5kgf (14.3lbs) |

| Handle Length (Effective Maximum) | 250mm (9.84inch) |

| Weight (Main unit + Handle) | 15.8 kg (34.8lbs) |

Model: MC-5 : 500kgf (1100lbs)

| Model | MC-5 |

|---|---|

| Load Rating | 500kgf (1,100lbs) |

| Wire Rope Diameter | φ6mm (6×37) (1/4inch (6×36)) |

| Winding Wire Rope | 5 or 7 Wraps |

| Hauling Tension | 7kgf or more (15.4lbs or more) |

| Gear Ratio | 8.9 : 1 |

| Handle Force | 8.5kgf (18.7lbs) |

| Handle Length (Effective Maximum) | 250mm (9.84inch) |

| Weight (Main unit + Handle) | 17.8 kg (39.2lbs) |

Model: MC-10 : 1,000kgf (2200lbs)

| Model | MC-10 |

|---|---|

| Load Rating | 1,000kgf (2,200lbs) |

| Wire Rope Diameter | φ8mm (6×37) (5/16inch (6×36)) |

| Winding Wire Rope | 5 or 7 Wraps |

| Hauling Tension | 13kgf or more (28.7lbs or more) |

| Gear Ratio | 12.6 : 1 |

| Handle Force | 10.8kgf (23.8lbs) |

| Handle Length (Effective Maximum) | 300mm (11.81inch) |

| Weight (Main unit + Handle) | 20.1 kg (44.3lbs) |

Model: MC-20 : 2,000kgf (4,400lbs)

| Model | MC-20 |

|---|---|

| Load Rating | 2,000kgf (4,400lbs) |

| Wire Rope Diameter | φ9mm (6×37) (3/8inch (6×36)) |

| Winding Wire Rope | 5 or 7 Wraps |

| Hauling Tension | 25kgf or more (55.1lbs or more) |

| Gear Ratio | Normal Winding 20:1 Quick Winding 4:1 |

| Handle Force | 13.0kgf (28.7lbs) |

| Handle Length (Effective Maximum) | 370mm (14.57inch) |

| Weight (Main unit + Handle) | 31.3 kg (69.0lbs) |