Features of mini MAXPULL WINCH

This is a light and compact mini winch that has been developed for light work for personal use. This winch is not suitable for industrial or heavy duty use. This winch is suitable for lifting of drop curtains, setting tennis / volleyball nets, or jet ski in-vehicle installation work, etc.

Model: PM-100 / PM-200

Simple operation

As the machine efficiency is high, the hand load during operation is very light compared to that of competitors’ winches and you can carry out the work easily. This winch has a compact design with minimal weight and very convenient to carry or move. In addition, the main unit can be easily attached using predefined bolts. Another major feature is that each part is made by press processing, and the whole winch is assembled with bolts, so it can be easily disassembled. If a repair is necessary, anyone can easily repair and assemble the winch by following the instruction manual and purchasing the parts.

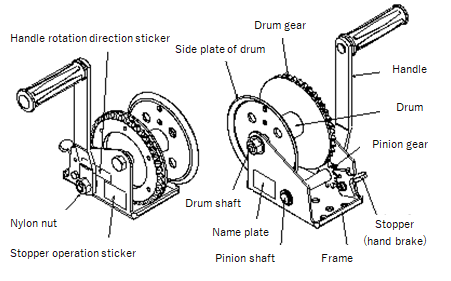

The brake type of PM-100 type is a manual (claw) brake.

The winding can be rotated with the claw engaged, but please remove theclaw when unwinding (unlock the claw by holding the handle with a hand or unlock it when there is no load). To wind the wire rope safely, rotate the handle in the winding direction shown on the sticker attached to the side surface of the frame. If you rotate the handle clockwise in the winding direction, the drum rotates counterclockwise. If the wire rope is wound at this time, the status is normal. Be sure to ensure 5 turns or more in the initial winding of the drum.

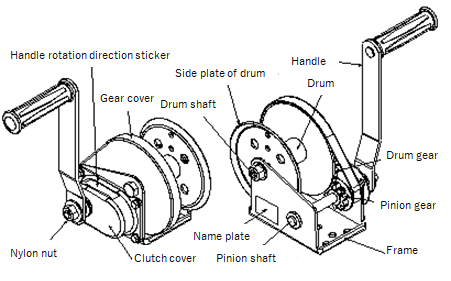

The brake type of PM-200 type is automatic mechanical brake.

If you rotate the handle in the winding direction (clockwise direction), it makes a clicking sound, but if you rotate the handle in the unwinding direction (counterclockwise direction), it does not make a sound. If you repeat this operation 3 to 4 times and the handle always makes a clicking sound when you rotate it in the winding direction, the mechanical brake is normally working. Wind up the wire rope normally by rotating the handle in the winding direction shown on the sticker attached to the clutch cover. If you rotate the handle clockwise in the winding direction, the drum rotates counterclockwise. If the wire rope is wound at this time, the status is normal. Be sure to ensure 5 turns or more on the initial winding of the drum.

Cautions on handling

Do not use PM-100 type for lifting loads vertically. The brake type of PM-100 type is manual brake. The winding can be rotated with the claw engaged, but please remove theclaw when unwinding (unlock the claw by holding the handle with a hand or unlock it when there is no load). PM-200 or more is equipped with built-in mechanical automatic brake (clockwise rotation executes winding and counterclockwise rotation executes unwinding and it stops even if you release your hand).

Example of mini MAXPULL WINCH usage site

Mini MAXPULL WINCH product list

Model: PM-200 : 200kgf (440lbs)

| Model | PM-200 |

|---|---|

| Load Rating | 200kgf (440lbs) Below each reference layer |

| Drum Capacity | φ4mmX25.0m (82.0 ft) ( 9 layers) φ5mmX15.5m (50.9 ft) ( 7 layers) |

| Gear Ratio | 4.1 : 1 |

| Handle Force | φ4mm : 11.6kgf (25.6lbs) : 6 layers (14.0m(45.9ft)) φ5mm : 11.7kgf (25.8lbs) : 5 layers (9.5m (31.2ft)) |

| Handle Length (Effective Maximum) | 205mm (8.1inch) |

| Weight (Main unit + Handle) | 3.3 kg (7.3lbs) |

Model: PM-100 : 100kgf (220lbs)

| Model | PM-100 |

|---|---|

| Load Rating | 100kgf (220lbs) Below each reference layer |

| Drum Capacity | φ3mmX40.0m (131.2 ft) ( 12 layers) φ4mmX25.0m (82.0 ft) ( 9 layers) φ5mmX15.5m (50.9 ft) ( 5 layers) |

| Gear Ratio | 4.1 : 1 |

| Handle Force | φ3mm : 5.9kgf (13.0lbs) : 8 layers (22.5m (73.8ft)) φ4mm : 5.8kgf (12.8lbs) : 6 layers (14.0m (45.9ft)) φ5mm : 5.9kgf (13.0lbs) : 5 layers (9.5m (31.2ft)) |

| Handle Length (Effective Maximum) | 205mm (8.1inch) |

| Weight (Main unit + Handle) | 2.7 kg (6.0lbs) |